7 Conclusions

7.5 Examples of context: televisions, aircraft and soap powder

Designs are not just differentiated by what they do and how they do it, or what they look like, but also by the wider social and economic contexts in which they are created and used. To illustrate this, let us return to the design of television sets.

Traditional television manufacture is a global industry, and a cluster of companies, including Sony and their suppliers, are located in South Wales at the time of writing (2000). This cluster was the result of considerable inward investment several years ago and is now under threat from new flat-screen technology (see Gas plasmas and electron guns).

The South Wales companies concentrate on the production of a traditional product and incremental modifications, such as replacing analogue electronics with digital electronics and changing the aspect ratio (width-to-height proportion) of the screens. The manufacturing plant is terrifyingly efficient. Sony maintains its niche by manufacturing and distributing at minimum cost. To do this it needs to control its supply chain and both influence and respond to its customers. The production of the CRT is costly, requiring expensive, dedicated machinery. To maintain a dominant position, Sony outsources the very large plastic injection mouldings for the cases of televisions. These injection moulding companies are in the region because of the concentration of inward-investing global companies such as Sony.

Gas plasmas and electron guns

Flat-screen televisions use a completely different technology from the conventional cathode-ray tube sets which have been around, relatively unchanged excepting the advent of colour, since the 1940s.

In cathode-ray tube televisions, the image is made by firing a beam of electrons (emitted by a cathode, hence the name) at the screen, which is coated with a phosphor layer that glows when it is hit by the beam. The beam scans across the screen in lines, with the intensity varying constantly to build up the picture. The beam is scanned 25 times a second, so the image appears constant. The reason that CRT-based televisions are quite deep is that there must be room for the beam to be pulled up and down (by electromagnets) to the top and bottom of the screen after leaving the cathode.

Since the late 1990s flat screens have become available (and I am not talking here about ‘flatter tubes’, which are still just CRTs). These flat screens are based on tiny glowing plasma cells. The screen is made up of many hundreds of thousands of these cells. The television can be made as flat as the associated electronics will allow, hence televisions with these screens are much thinner than those using CRTs. They are probably suitable for hanging directly onto a wall.

Interestingly these moulding companies work differently from traditional injection moulders, called ‘trade moulders’ in the UK. These trade moulders were established by engineers with tool making abilities. They were supported by the plastics expertise of large chemical companies such as ICI. Their particular expertise lies in designing tools that can be filled with molten plastic, efficiently creating mouldings which are dimensionally stable across hundreds of thousands of repetitions. A product designer can go to these companies with a shape and rely on them to produce it to a specification. Sony, however, separate tool design from the moulding process, so maintaining a more detailed control over its suppliers. The moulding companies are all within a day's delivery of the assembly plant. The context of the design of the television case is thus one which allows Sony to maintain full control over its production, including all suppliers. Sony wants to reduce its uncertainties and risks in a market which is highly competitive.

Exercise 12

How are designs and designing in Sony responding to competitive pressures?

Answer

There are several points which you could have picked out:

- Variant designs are produced in high volumes, so maximizing use of available capacity.

- New cases are produced by suppliers in a highly controlled way so that 84 production plans and schedules are not disrupted. This is critical for high-volume production.

- There is a mixture of variant and innovative designs.

- Existing televisions are regularly re-styled to ensure that they remain popular in the market.

Sony represents a context for design which is driven by a mature competitive market, and which is configured to let Sony have better control over its production than do the competitors.

Other contexts for design are the ways an industry is structured, its markets or even politics. Let us look at the aircraft industry which includes airframe designers such as Boeing or Airbus and engine designers such as Rolls-Royce or General Electric.

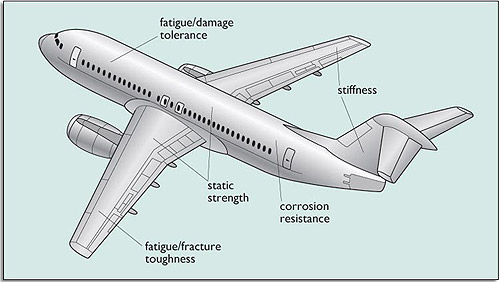

In the aircraft industry the life of a design and its variants is of the order of 40 or 50 years. Rolls-Royce maintains a full range of jet engines, some used in aircraft built in the 1960s. There are a number of key technologies, business relationships and supplier industries who come together to make an aircraft: electrical and hydraulic systems, structures, materials, aerodynamics and engines. Figure 64 shows the dominating design requirements at different points in the airframe.

As discussed in Section 6.5, fatigue is a very important concept in designing for the operating life of a product. The extent to which fatigue will occur in a particular design depends on how the product is used – the operating conditions. Unfortunately, detailed understanding of the long term effects of this fatigue is difficult to predict without extensive testing. A lot of the knowledge gained about fatigue is empirical. It is case-by-case and material-by-material. Patterns do emerge but experience shows that they must be interpreted with caution. For the long-lifetime products such as aircraft the ability to predict the effects of operating conditions and régimes is critical. I emphasise this because a lot of our perceptions of good design hinges on quality and more particularly reliability. Designers need to consider not only the static function of a product but how it is used – the typical operating cycle.

How are the design activities of airframe companies dependent on context? Consider materials development in the context of a company like Airbus. The industry, generally, is a user of advanced aluminium alloys because they are strong for their weight. This is clearly of importance for aircraft. Associated with each alloy is a large body of knowledge on performance from tests and in-service data. To develop and use a new alloy is a significant commitment.

Airbus is interested in new alloys such as aluminium–lithium alloy for use in airframes. Lithium is a light element (it has a low density), so if an aluminium–lithum alloy can be developed with comparable properties to existing alloys, then it will reduce the weight of the airframe. The consequent effect to the airline in reduced operating costs or increasing payload could be a major commercial benefit. However, Airbus does not develop alloys. They are developed and promoted by alloy producers, so the product-design company works closely with the metal-design company, who also work with Airbus's competitors. The context of design becomes more and more intricate.

To add to this complexity, if a competitor such as Boeing is working on such an alloy then Airbus cannot afford not to parallel the work, even if they know that the prospects of success are remote. The penalty of failure is failure of the company. Designers in the different companies watch each other, not in the sense of industrial espionage, but in the open forums where companies that simultaneously compete and collaborate meet. The same principle applies to aeroengine companies. A new alloy that will operate at higher temperatures makes a more efficient engine, so if General Electric is working on a new class of material then Rolls-Royce also has to work on this class.

Unfortunately the ways that these complex sets of interrelationships behave changes from business to business. So what may be true of the aircraft industry cannot be generalised to the computer industry, or to telecommunications or software, for example. Furthermore the complexity of the interrelationships in a particular industry are determined not only by the technical issues, such as those discussed above, but also by broader economic issues.

In order to provide a contrast, compare the aerospace context with the design of packaging for household foodstuffs and cleaning products. Unilever and Procter & Gamble compete fiercely in a global market for soap powder. They try out new packaging in test markets and watch each other's test markets carefully.

In the 1990s plastic flexible bags of soap powder (the usual pack having been a cardboard box that stood upright on the sink) were introduced to one of the test markets. These sold well in the first month and maintained sales for a second month. So both companies became involved in a race to offer flexible packs world wide. As soap powder is sold in large quantities world wide, this required a considerable design effort to equip factories with the new tooling for the new packaging. The advantage to be gained in the market critically depended on the schedule for introduction of new designs of tooling to produce the machines to make the new packages. Although complex packaging requires a longer lead time in the setting up of a production line, the time scale involved is nevertheless a matter of weeks and months, rather than years. Thus ‘design’ operates quite differently in the world of soap powder from the world of airframes. Designers of soap powder can try out possibilities in markets, but aircraft designers only get one shot.